Machine vision Keep an eye on quality

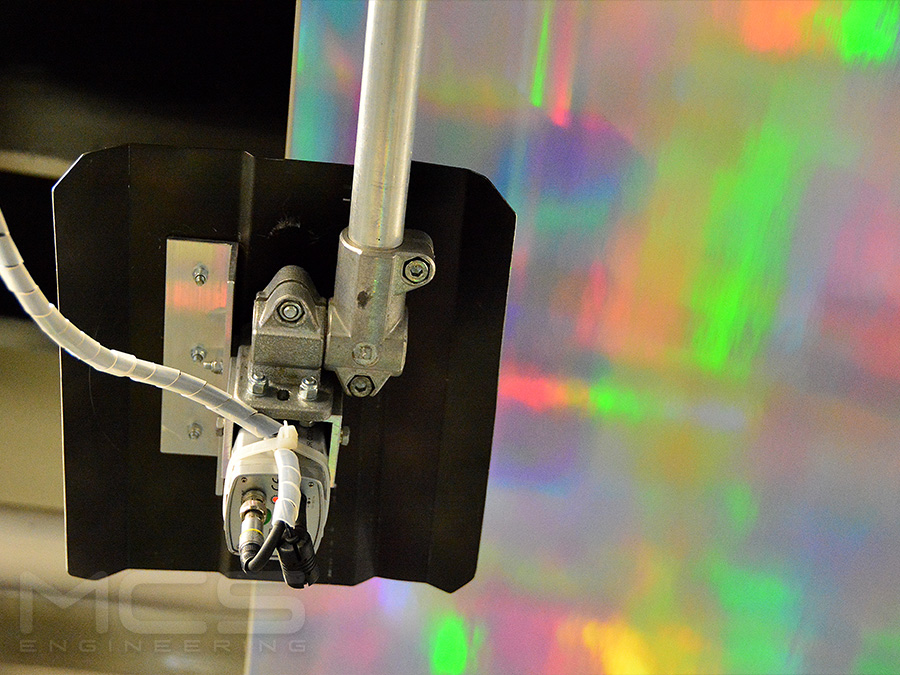

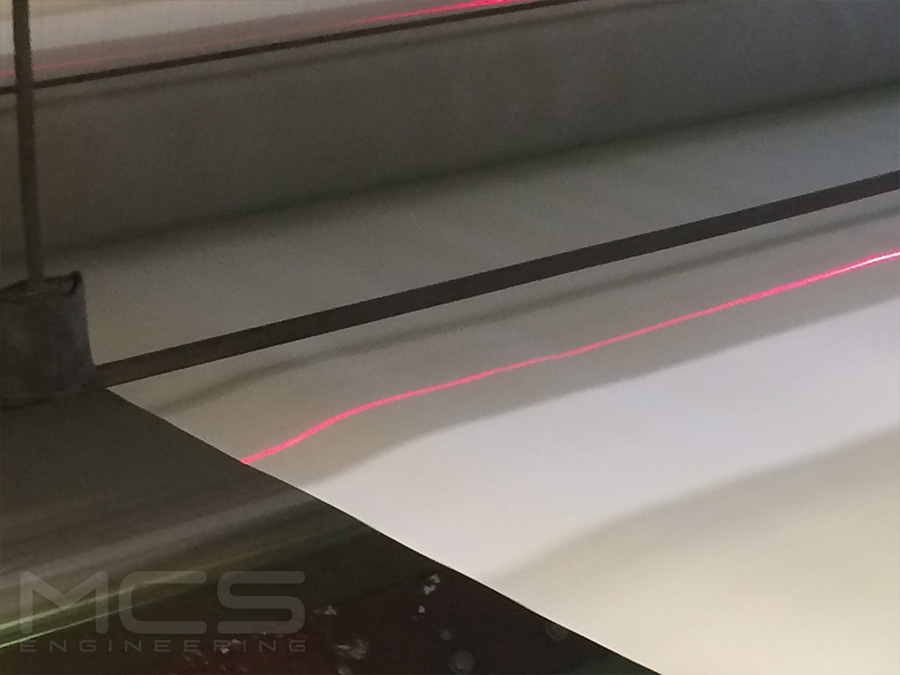

MCS Engineering developes and builds vision systems for a wide range of industries. Vision systems are ideal for detecting defects, for example in flat sheet products, quality control of products or prints and monitoring processes and logistics flows.

All our vision systems are built from industrial quality components and software is developed in-house for a high quality system with high reliability. Light sources are also developed and built by MCS Engineering. Most of our vision solutions are custom built. We analyze the problem and try to develop a solution for the machine vision problem in question as well as possible. This method may take a little more time than grabbing a standard smart camera, but the result achieved is often much better and more reliable.

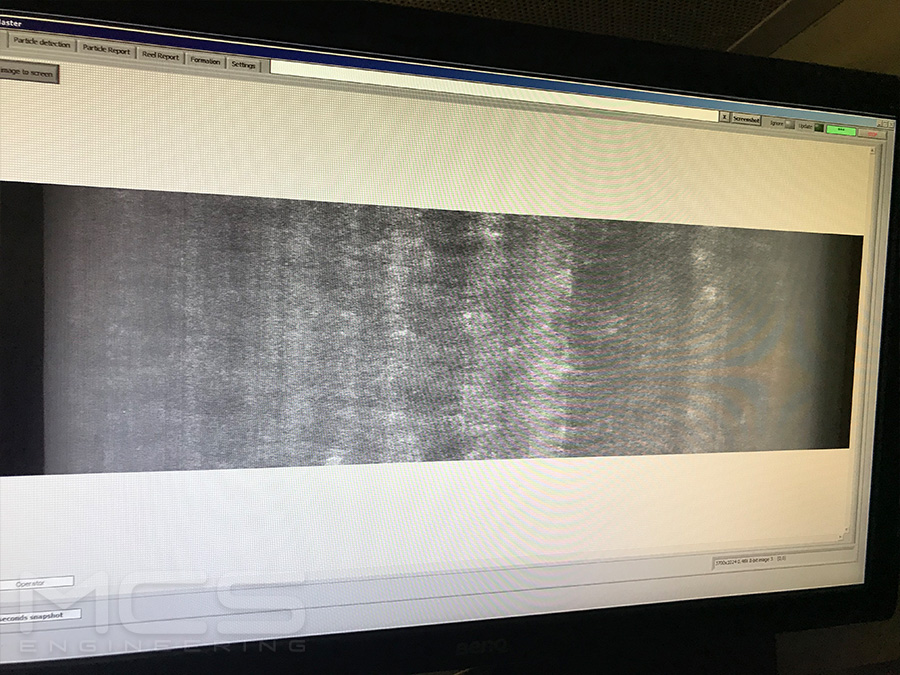

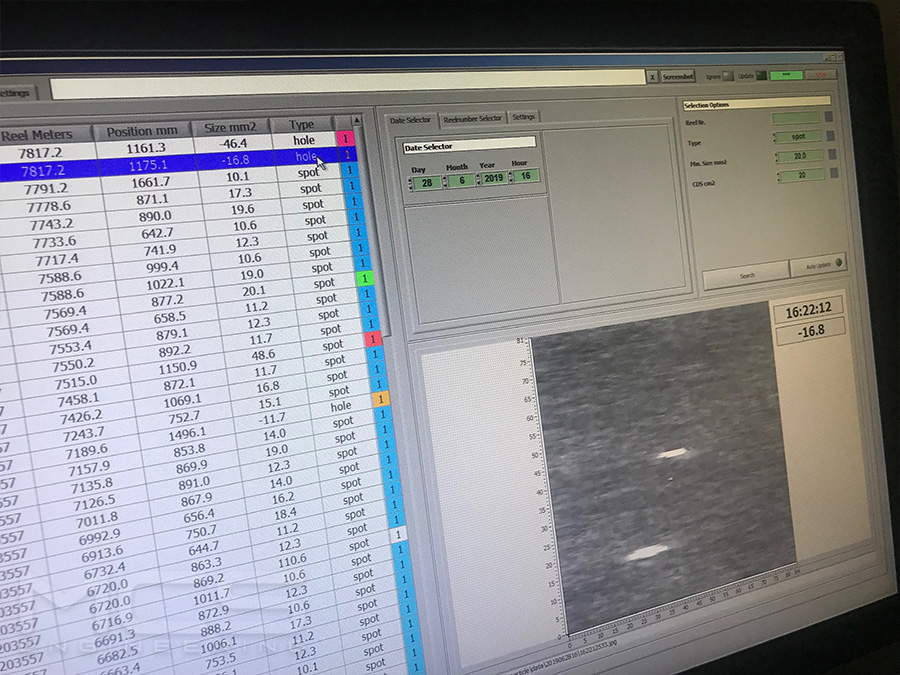

Defects detection

MCS Engineerings Vision Defects Detection System helps with the quality optimization of production processes. Defects, such as holes, dirt and stains, are easily detected in flat sheet products. The system is extensively expandable for any with of the production process and high machine speeds are no problem.

Unlike other systems, you do not need to build a database of pre-classified defects here. The drawback of such a method is that many defects are still not detected and this solution is also very laborious. The MCS Engineering system independently defects deviations in the continuous process and classifies these deviations.

Quality measurement

Vision system automation can be used to inspect the presence / adsence, flaws, colors, characters or object recognition and more, such as surface scanning, surface inspection, crack detection, contour defection and position control.

Checking the quality and correctness of prints and barcodes are also tasks that vision systems cn perform very well and effectively.

Poor project quality or interruptions in the production process can have far reaching implications for every company. To minimize these risks and to ensure that your products are of a perfect quality, you can use our in-house developed Vision Quality Control.

Vision monitoring

Keep a grip on production processes and logistic flows through automated vision solutions. With vision monitoring you collect data and visualize real-time industrial and logistics processes.

Based on sophisticated information, you make valuable decisions about processes and installations. Thanks to an extensive historical insight, you act on hard facts and you know exactly where each product was at any time and in which condition.